High-Quality Inner Parts for TMT Quenching Boxes

At Steel Trade Kings, we supply precisely engineered inner components for TMT quenching boxes to ensure efficient, uniform cooling during the thermo-mechanical treatment process. These parts play a crucial role in achieving the desired strength, ductility, and finish of rebars in high-speed rolling mills.

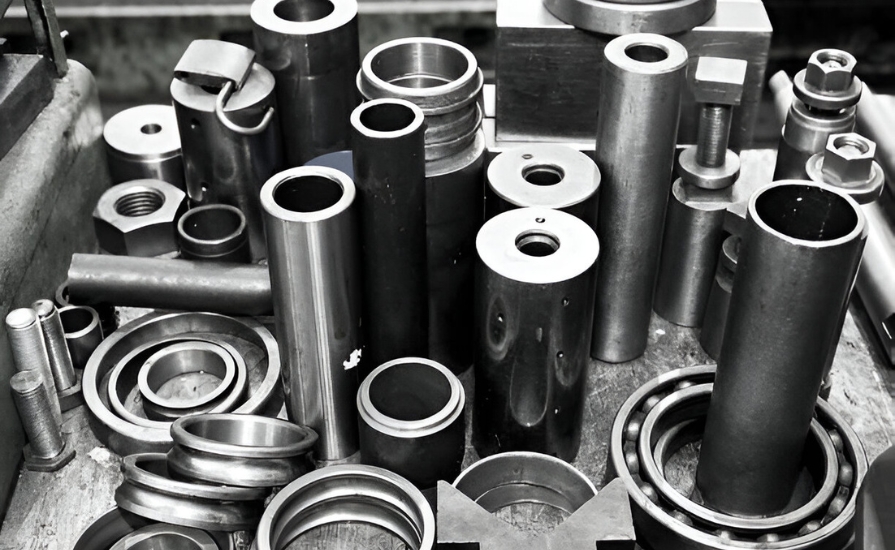

Our components—including nozzles, headers, pipes, clamps, and wear plates—are manufactured using corrosion-resistant materials and tested for high-pressure performance. Designed for easy maintenance and long service life, they ensure optimal water flow and temperature control during quenching.

Why Choose Steel Trade Kings

With decades of expertise in the steel manufacturing sector, Steel Trade Kings is a trusted name for precision-engineered machinery and custom solutions. We focus on delivering high-quality systems tailored to the evolving needs of both domestic and international steel producers—helping drive efficiency, innovation, and growth across the industry.